Restaurants, hotels, motels, schools, and hospitals, what do they have in common? They all prepare and serve food. The problem occurs when pouring the liquid cooking fats from those foods or FOG (Fats, Oils and Greases), down the drain it will eventually cause sewage line blockage. The results of such blockage is the eventual cause of backups into roadways, water bodies, and even basements. This is not only hazardous, but is also a health hazard, and causes extensive property damage. For more information, please visit the following link: http://waterandsewer.org/education-and-community/fats-oils-and-grease-fog. Due to the damages and hazard of FOG, many cities require businesses to have grease interceptors. For example, New York City’s Sewer Use Regulations and carries monetary penalties of up to $10,000 per violation. So there must be a way of preventing greasy waste material? And If you want to “Clear the FOG”, the easiest method is to use a grease interceptor.

What are Grease Interceptors?

A Grease Interceptor also known as a Grease Trap is a specialized plumbing device for intercepting most greases. They are designed to block fats, oils and greases (FOG), or “clear the FOG” before they can enter sewers

A Grease Interceptor also known as a Grease Trap is a specialized plumbing device for intercepting most greases. They are designed to block fats, oils and greases (FOG), or “clear the FOG” before they can enter sewers

How do Grease Interceptors work?

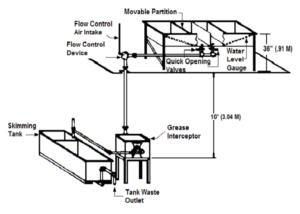

The purpose of a grease interceptor is to separate fats, oils, greases (FOG), and other deleterious waste materials at the source. As the wastewater cools, the fat, oil, and grease harden and the food solids settle. The FOG, being lighter than water, floats to the top of the grease trap. The wastewater is forced through the grease trap and out to the sanitary sewer. FOG fills a grease trap from the top of the tank to the bottom.

Design Criteria

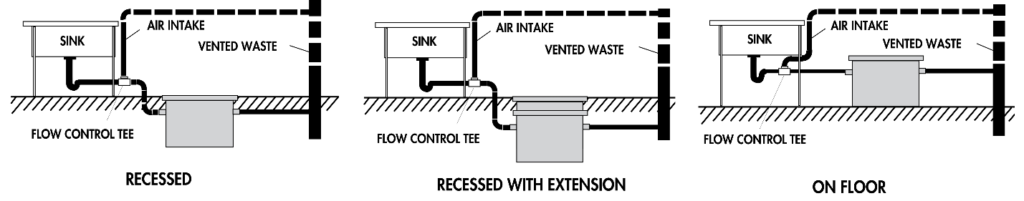

The design criteria is quite important as it is determined by local codes following the guidelines set for by the Plumbing & Drainage Institute (PDI), which tests and rates Grease Interceptors. Be sure to follow the accepted industry, within Canada or the US, and the PDI Standard (PDI-G101) for interceptors. They are typically installed at the fixture.

Image taken from: http://static1.1.sqspcdn.com/static/f/1395156/27911530/1526888927933/Standard_PDI-G101_revised_2017.pdf?token=9HOnoZg6i6GPsFVRpzee7maGAQ4%3D

FOG should be removed from the source of complete flow of waste, as close to the designated area as possible. However, some codes and regulations often restrict engineers as to where they may place a grease interceptor, and can be based on specific locations of each interceptor, or the type of grease interceptor.

Flow Rate (Single Fixture):

As per the Watts General Procedure document for sizing Grease interceptors

- Convert the capacity from cubic inches to gallons per minute (GPM): ___ cu. in. / 231 = ___ GPM.

- Adjust for displacement: ___ GPM x 0.75 = ___ GPM.

The result is the flow rate required to drain the sink in one minute.*

*Note: If drain down time is not critical, an interceptor with a lesser flow rate up to 1/2 the calculated flow rate may be specified.

Below, you will find an illustration of a typical configuration:

Image taken from: http://media.wattswater.com/s-wd-inter.pdf

Flow Rate (Multiple Fixtures):

You will need to determine the flow rate for each fixture to be serviced by the interceptor, and if you have multiple fixtures, we recommend using the ATS Email Spec Service to size the correct Grease Interceptor for your project. This can be a lot of information, and quite cumbersome in your commitment to clear the FOG.

Tools to size Grease Interceptors:

ATS SPEC TOOL: We can assist you with your options to size your interceptor, as you can have access to 10+ formats, and we’re ready to provide you with any assistance.

Let ATS assist with your next food service facility project. Login today to download your project specification, and don’t forget your grease interceptor! We can help you with our Specification tools, which allows you to write and download your specification.

Share this article