When looking to choose the right flush valve for your project, the application and conditions must be considered. A variety of factors will help decide which product will work best.

Flush valves are simply automatically timed self-closing valves. They are broken down into two groups: Piston-types and Diaphragm-types. Although each has different characteristics, they both work with the initial gravitational pull that allows water to flow through the toilet when flushed. Flushometers reset faster than gravity alone, as the mechanisms help force the water down.

Additionally, each type of urinal and/or toilet flush valve has an upper control chamber and a lower supply chamber connected by a bypass. The bypass in both the diaphragm and piston valves is a small hole or orifice that only measures between 0.020 inches and 0.030 inches in diameter. Both technologies help provide significant water savings per flush.

It is important to note a variety of factors when selecting which flush valve type best suits your application needs.

Piston Valve:

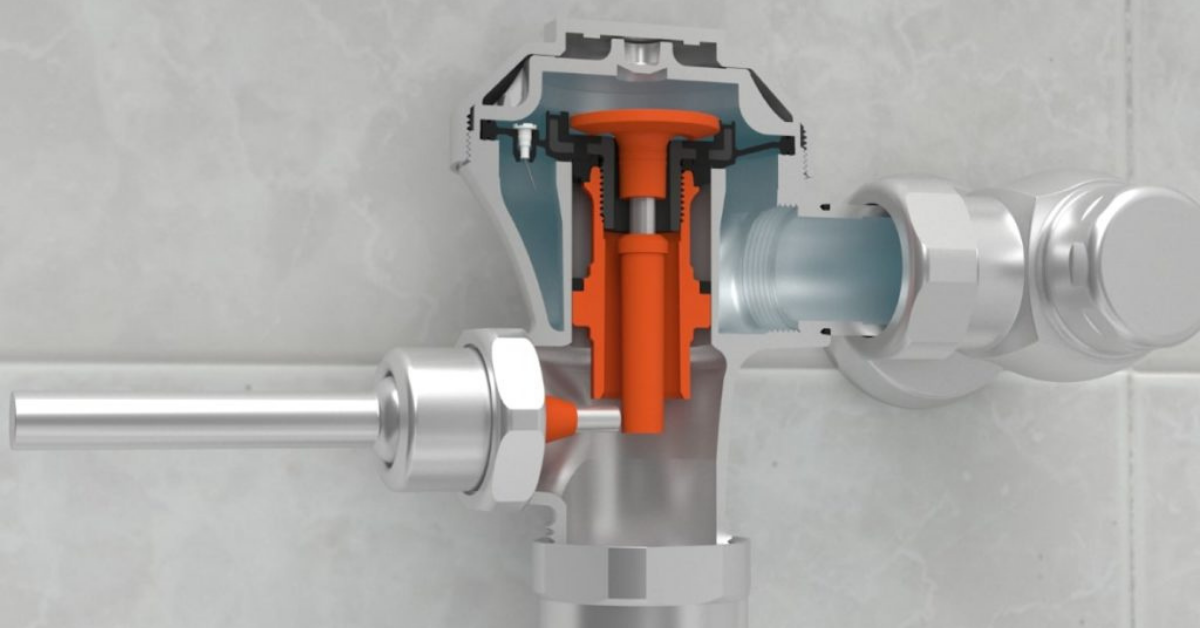

The piston valve is made up of a molded cup that separates the upper and lower chambers in the flushometer. The sliding motion within the valve body cylinder thrusts the water down when flushed, however, this movement is longer than the flexing movement of the diaphragm.

The piston valve is made up of a molded cup that separates the upper and lower chambers in the flushometer. The sliding motion within the valve body cylinder thrusts the water down when flushed, however, this movement is longer than the flexing movement of the diaphragm.

Piston-type valves have three points of sealing. The first is located at the main seat where the piston seals at the bottom of the valve body. The second is situated at the lip seal, preventing fluid from moving across the cylinder head. The third resides on the relief valve seat which opens with the right amount of water pressure. A common flaw the piston tends to possess is the lack of longevity. Oftentimes the valve can get cocked or particularly stuck in a position as it wears, and due to the extra sealing point, it is more likely to deteriorate which can cause water leakage.

More maintenance is also required with this type of valve. It is crucial to check the internal adjustment screw for flow in order to function properly and reduce waste. The minimum flow should be 15PSI +/- and maintained regularly. One must consider the environment to which this system will operate, as the piston runs better in low and weak pressure systems with cleaner water conditions.

Diaphragm Valve:

The diaphragm valve separates the upper chamber from the lower chamber using a flexible rubber disk. This valve operates on a more reliable “flex” movement, which lifts the seal to allow the water to flow through.

Unlike the piston valve, the diaphragm valve has two points of internal sealing. The valve barrel seals water in the upper chamber pressing the diaphragm down onto the valve seat. When the valve barrel is open it breaks the seal allowing water from the lower chamber on the inlet side to push the diaphragm up off the valve seat allowing water to pass through until the pressure has equalized. The diaphragm valve has a simpler operating mechanism which also makes it easier to assemble. It is important to take note of this based on who will oversee performing maintenance duties. In addition, the centric design makes it highly unlikely for the valve to get cocked or stuck.

The diaphragm-type check valve is currently dominating the North American market because of its durability, reliability, and ultimately, the low maintenance cost. This means North American plumbers will be more familiar with the valves and better understand how the mechanics operate. One must consider the environment to which this system will operate, as the diaphragm runs better in high traffic, poor water conditions and high back pressure.

Comparing Flush Valves:

Conclusion:

Overall, the diaphragm valve holds a greater advantage over the piston valve due to its simplicity and heavy traffic environment. A task that can be completed with fewer problems and saves users time and money is ultimately the wiser decision. However, the amount of usage on these toilets and/or urinals is an important piece of information to use in the decision-making process.

ATS can help make sure your valves best suit your needs

Share this article